Modular Solutions

Cleanroom HVAC

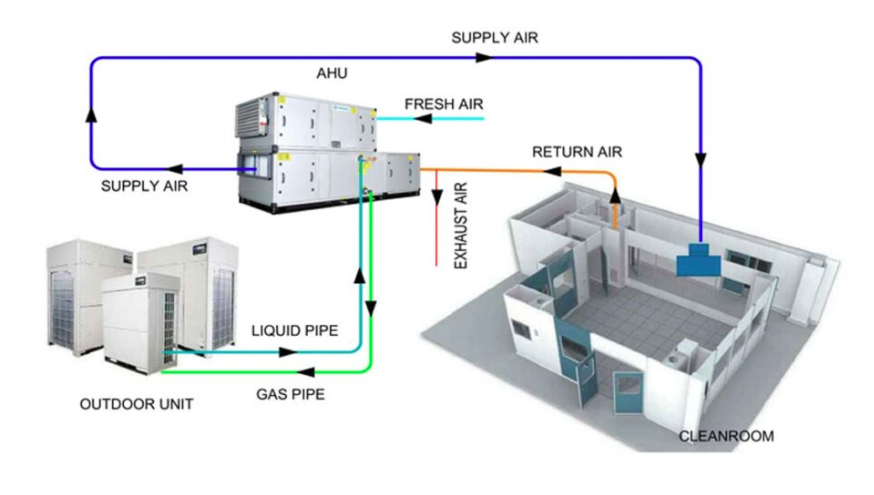

Cleanroom HVAC systems are specialized, highly engineered solutions that play a critical role in maintaining contamination-controlled environments for industries such as pharmaceuticals, healthcare, food, and electronics.

They require precise design, careful installation, and ongoing maintenance to ensure strict compliance with standards for:

- Air Cleanliness

Controlling particulate matter through advanced filtration. - Temperature & HumidityMaintaining stability for sensitive processes.

- Airflow & Pressure Ensuring proper pressurization and directional flow to prevent contamination.

Our HVAC solutions are designed for efficiency, reliability, and sustainability, ensuring cleanrooms remain fully compliant with GMP, ISO 14644, and FDA guidelines while supporting long-term operational success.

HVAC Systems includes below major items

- Low side HVAC

- High Side HVAC

- - Chilling unit

- - Air Cooled Condensing units (DX System )

- - Air Cooled Chiller

- - Water Cooled Chiller

- Cooling Tower

- Chilled water pumps, Cooling water pumps

- Required Valves & Accessories like Butterfly valve, NRV’s, Expansion Joints etc

- Piping with Insulation

- Manifolds with 2 way /3 way modulating valve with actuators

- Measuring instruments for Temperature, Pressure and Fluid Flow

- Air Handling units

- Ducting with insulation

- Fire dampers, Volume control damper with required actuators

- HEPA Modules

- Aluminum grills / diffusers with volume control damper ..etc.

The HVAC system is the “Heart” that makes sure you can obtain the certifications required for your cleanroom, while the walls and ceilings are the “Body” of the cleanroom area.

Air Handling Unit

Efficiently conditions and circulates air to maintain optimal temperature, humidity, and air quality in HVAC systems.

Fan Filter Unit (FFU)

Engineered for cleanroom ceilings, these units ensure uniform airflow, enhanced particle control, and hassle-free installation.

Terminal HEPA Box

High-efficiency air filtration for clean, controlled environments across pharma, healthcare, food, and microelectronics.

Diffusers/Grills/Dampers

Jet Diffusers, Air Diffuser, Slot Diffuser, Round Diffuser

• Aluminum Grill, Diffuser Grill, Inline Fan

• Volume Control Damper, Fire Damper

• Air Louvers, Aluminum Louvers

Dehumidifiers

Engineered Dehumidifiers: Precisely designed to meet the most stringent humidity control needs across pharmaceuticals, food, chemicals, defense, electronics, and power industries.

Air Handling Units (AHU)

Robust Construction

High-performance AHUs constructed from 16G galvanised iron with powder coating, available in vertical or horizontal configurations. Optional stainless steel construction for corrosive environments. Modular, walk-in design facilitates maintenance and accessibility.

Key Specifications

- Flexible cooling options: chilled water, VRV, or direct expansion

- Airflow capacity: 500 – 30,000+ CFM

- Direct drive plenum fans for low noise operation

- Automated pressure and flow control systems

Smart AHU: Intelligent Air Management

Energy Optimisation

EC fans with permanent magnet motors deliver up to 25% energy savings, extending to 60% with optimised configurations. Modulating dampers and variable speed control maintain efficiency across load variations.

Smart Integration

BMS-compatible controls with real-time monitoring accessible via PC, tablet, or mobile device. Integrated automation enables predictive maintenance and remote diagnostics for reduced downtime.

Enhanced Features

Optional UV lamps for sterilisation, heat recovery systems, and advanced filtration. Cooling capacity range: 30 – 800 kW, accommodating diverse application requirements from laboratories to large-scale manufacturing.

Fan Filter Units (FFU)

Ultra-Clean Air Delivery

Self-contained systems integrating HEPA filters, fans, and intelligent controls. Provide continuous supply of particle-free air for cleanrooms, laboratories, and controlled environments. Efficiently eliminate hazardous airborne particles from recirculating air streams.

Localised Positive Pressure

Create targeted positive pressure zones, minimising contamination risks from ceiling bypasses. Unlike conventional pressurised plenums, FFUs deliver stable, energy-efficient performance with superior contamination control.

Pharmaceutical & Healthcare

Widely deployed across health sciences, pharmaceuticals, food and beverage, and microelectronics sectors. Ensure process reliability, operator safety, and regulatory compliance with ISO and GMP standards.

Terminal HEPA Filtration Systems

Precision Filtration

Performance Highlights

- Durable construction with secure clamping mechanisms

- Configurable size, airflow capacity, and filter type

- Low noise and energy-efficient operation

- Long service life with reliable performance

- Improved indoor air quality and contamination control

Diffusers: Optimised Air Distribution

Ceiling Diffusers

Traditional and low-profile designs for standard ceiling installations, providing multi-directional airflow with uniform temperature distribution.

Linear Slot Diffusers

Architectural linear designs for perimeter installations, offering precise airflow control and discreet aesthetic integration.

Swirl Diffusers

Rotational airflow patterns for large-space applications, ensuring draft reduction and enhanced occupant comfort.

Air distribution components designed to evenly supply conditioned air within cleanrooms and HVAC systems. Features draft reduction, uniform temperature distribution, and architectural finishes to match building aesthetics whilst maintaining performance.

Dampers: Precision Airflow Control

Manual & Motorised Operation

Available in manual or motorised configurations for flexible system integration. Enable precise air balancing and shut-off control for commissioning and maintenance operations.

Environmental Regulation

Control temperature and humidity levels within specified parameters. Contribute to energy optimisation by modulating airflow to match actual demand rather than fixed maximum rates.

Safety Integration

Support fire and smoke containment strategies through automatic closure mechanisms. Interface with building fire detection systems for coordinated safety responses.

Grilles: Air Return & Supply Management

Controlled Airflow Distribution

Quality Outcomes

AHU-Integrated Dehumidification Systems

Construction Features

Thermal break aluminium profiles prevent condensation. Double-skin GI panels with PUF insulation. Inner sheet options: GI coated, SS 304, or SS 316 for corrosion resistance.

Control System

PLC + HMI system with 4.5″ display or 7″ touch interface. Fully integrated BMS compatibility. Data logging and remote access capabilities for predictive maintenance.

Reactivation Module

Heating options: electrical, gas, or steam input. SRPHCS (Self-Regulating Precise Heating Control System) reduces energy consumption. Pre/post cooling and heating modules available. VFD-controlled fans optimise process air handling.

Rotor Specifications

Swedish-origin rotor wheel in vertical configuration. Durable construction ensures long service intervals. Optional FC centrifugal fans (standard) or EC/plug fans (high-efficiency).

Comprehensive Environmental Control Solutions

Air Handling

Standard AHU, Smart AHU, and specialised terminal units

Filtration

FFUs, terminal HEPA systems, and advanced filter banks

Distribution

Diffusers, grilles, and duct accessories for complete systems

Control

Dampers, VAV systems, and integrated automation platforms

Complete turnkey solutions from concept through commissioning for cleanrooms, laboratories, pharmaceutical facilities, food processing plants, and microelectronics manufacturing environments. Our engineered systems deliver precise temperature, humidity, and particulate control whilst optimising energy efficiency and operational reliability.