Cleanroom Equipments

At Aastha, we understand the critical importance of maintaining regulated environments across industries. Our extensive range of cleanroom equipment reflects our commitment to providing high-quality, reliable solutions tailored to the specific needs of our clients.

By manufacturing in-house and following strict quality standards, we ensure that every piece of equipment delivers exceptional performance, safety, and compliance—giving you complete confidence in your cleanroom operations.

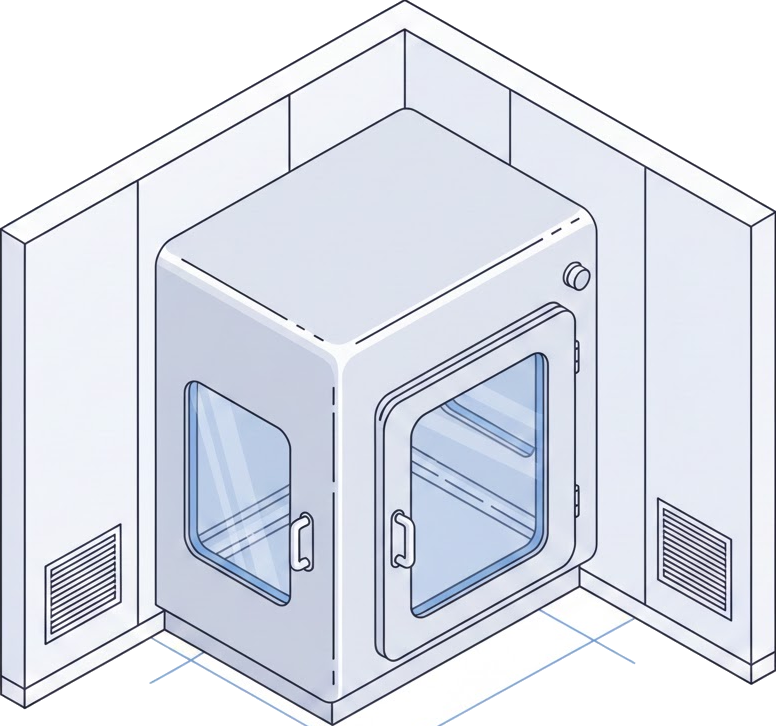

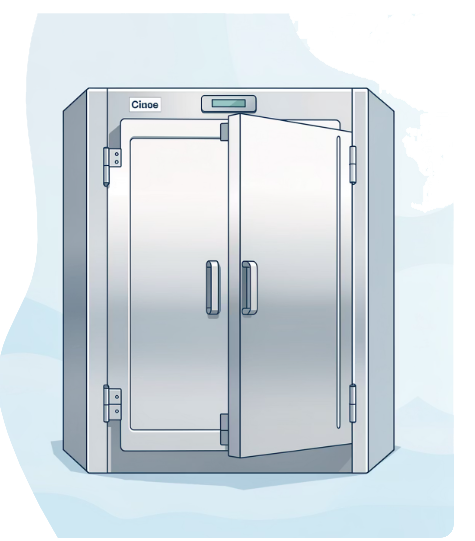

Pass Boxes

Safely transfer materials between clean and non-clean areas while preventing contamination and maintaining airflow control.

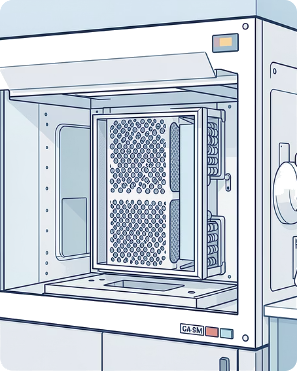

Laminar Air Flow

Provides a consistent, unidirectional airflow to keep laboratory workspaces clean, controlled, and free from contaminants.

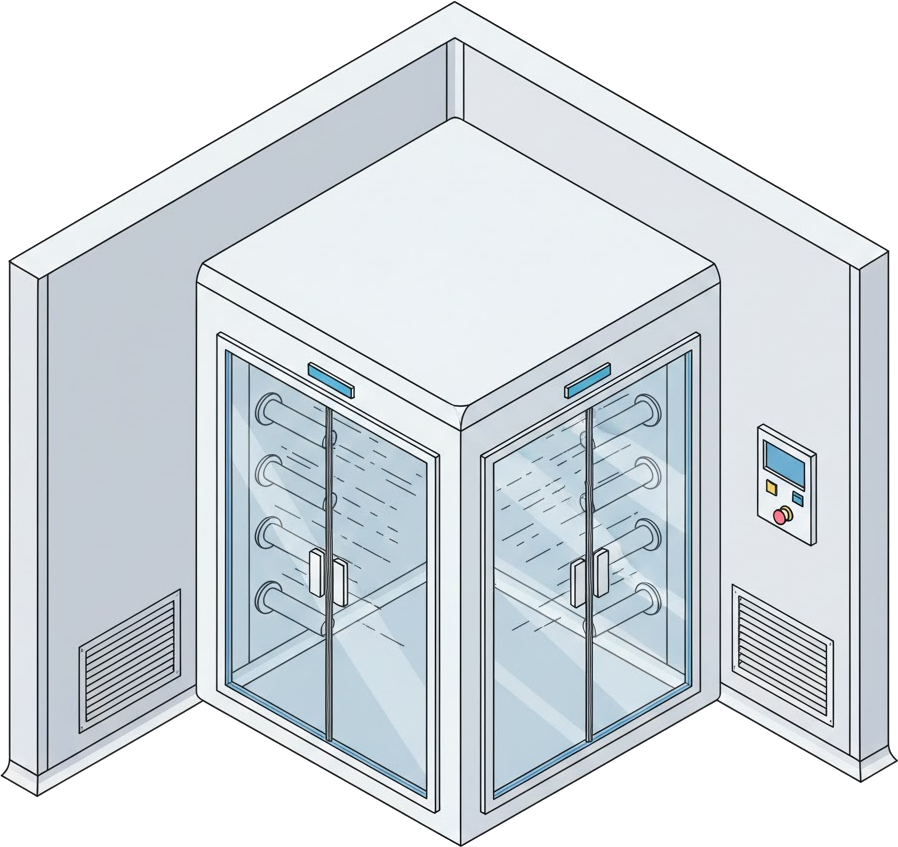

Air Shower

A specialized enclosed chamber that efficiently removes dust, particles, and contaminants from personnel and equipment before they enter a cleanroom

Mist Shower

Sprays a light mist on personnel leaving the cleanroom, effectively capturing particles and preventing contamination from spreading

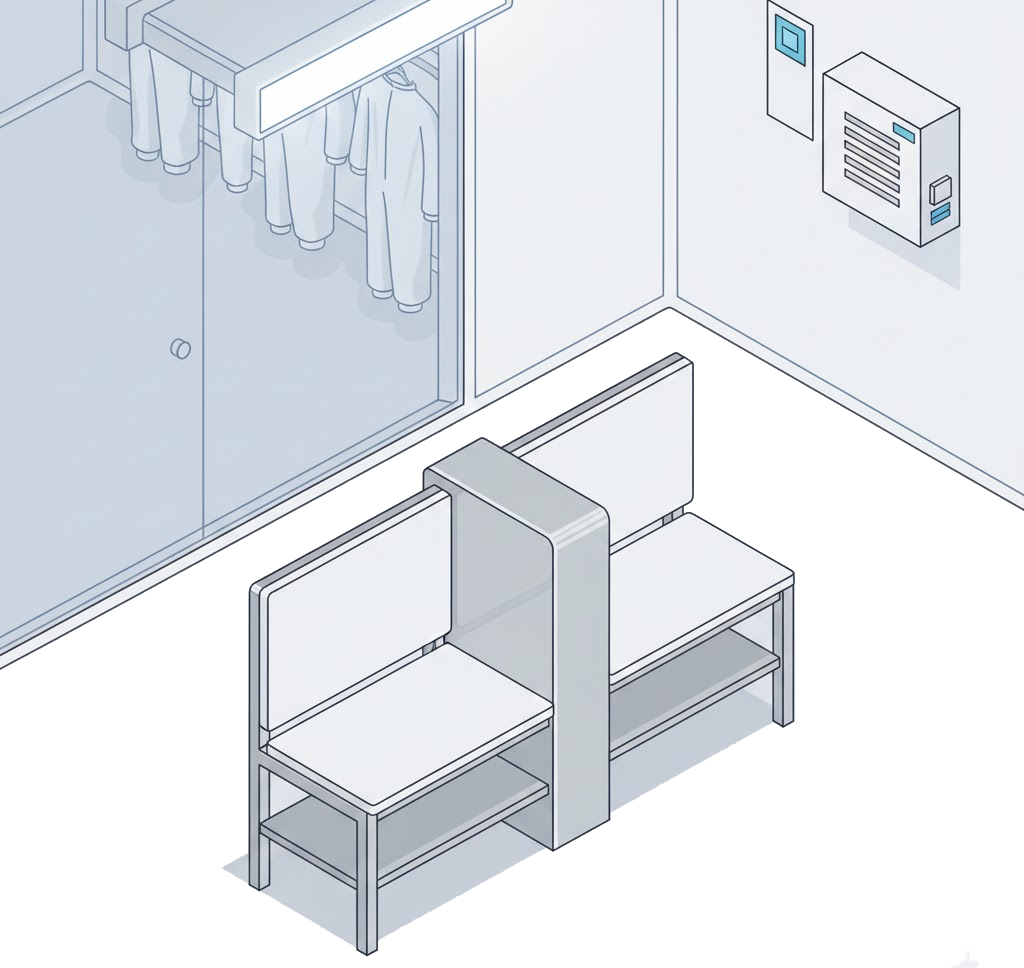

Cross Over Bench

Facilitate safe movement between clean zones while minimizing contamination, ideal for pharmaceutical, chemical, and food industries.

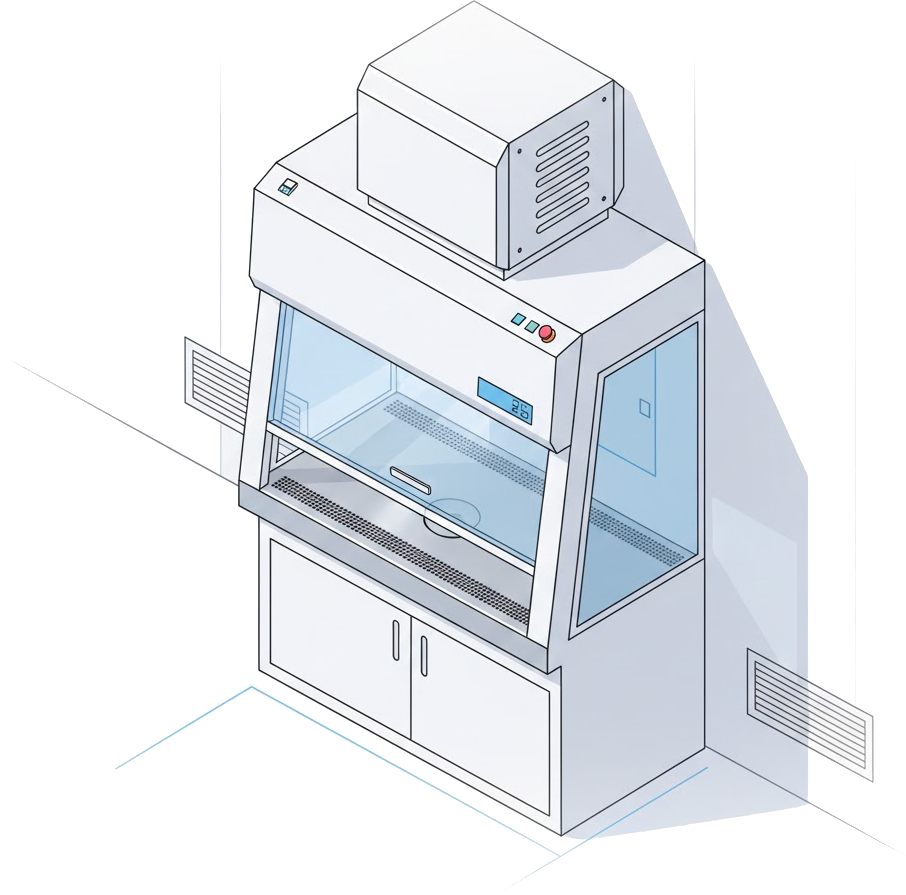

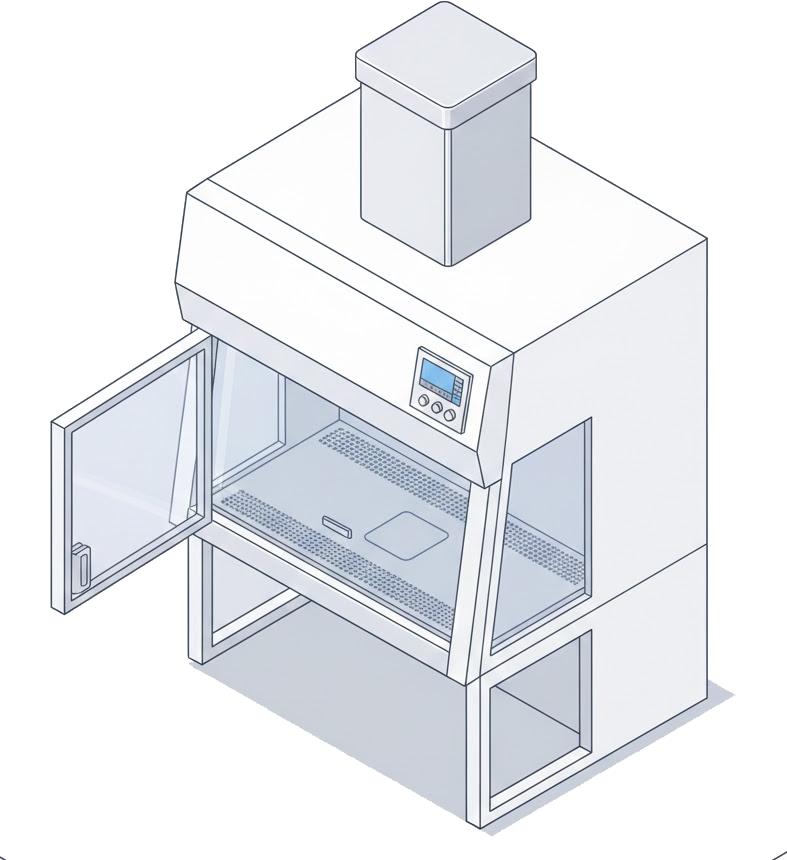

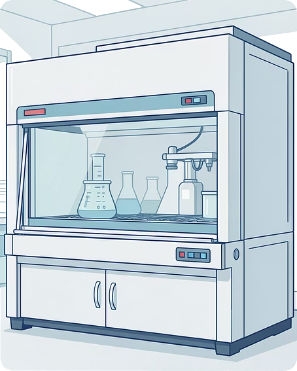

Bio Safety Cabinet

Capture airborne contaminants using laminar airflow and HEPA filtration, ensuring a safe and sterile working environment.

Advanced Cleanroom Equipment Solutions

High-precision equipment engineered for contamination control in pharmaceutical, biotechnology, and advanced manufacturing environments. ISO-compliant systems designed to maintain operational integrity whilst ensuring personnel safety and product purity.

Pass Boxes: Secure Material Transfer

Static Pass Box Specifications

Designed for material transfer between areas of equivalent cleanliness classification without active airflow systems. Constructed with double-walled panels featuring internal coving for easy cleaning and contamination control.

Electromagnetic Interlock

Prevents simultaneous door opening, maintaining pressure integrity and preventing airflow disruption between connected chambers.

LED Lighting & UV System

Integrated UV light with hour meter provides surface decontamination capability. LED illumination ensures clear visibility during transfer operations.

Material Options

Available in powder-coated mild steel, SS 304, or corrosion-resistant SS 316 construction for chemical compatibility.

Safety Features

Door status indicators and buzzer alert operators to door position, preventing accidental breaches in containment protocols.

Dynamic Pass Box: HEPA-Filtered Transfer

Engineered for transitions between classified and unclassified areas, dynamic pass boxes incorporate HEPA-filtered airflow maintaining ISO Class 5 conditions. High-efficiency filtration removes particles during material transfer.

Performance Specifications

- HEPA H14 filter: 99.997% @ 0.3µ

- Pre-filter F7: 90% @ 5µ

- Air velocity: 90 FPM ± 20%

- Noise level: 67 ± 2 dB

- Internal illumination: >500 Lux LED

Enhanced Features

- Electro-magnetic or mechanical interlock

- UV light with hour meter

- Pressure gauge with alarm

- DOP test port for certification

- 220–230V AC, Single Phase, 50 Hz

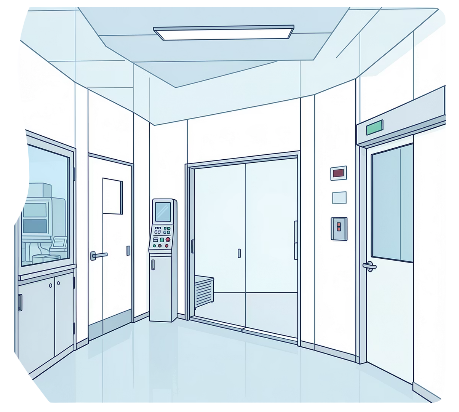

Air Showers: Personnel Decontamination

Walk-through units installed at cleanroom entrances remove dust and particles from personnel using high-velocity HEPA-filtered air. Adjustable stainless steel nozzles deliver targeted airflow from top and side jets, achieving ISO Class 5 conditions before entry into controlled environments.

Performance Specifications

Electromagnetic Interlock

Premium LED Lighting

Mist Shower Systems

Uniform Mist Coverage

Consistent particle capture throughout decontamination cycle.

Rapid Processing

Short cycle time enables high-throughput personnel access.

Energy Efficient

Optimised water usage and low power consumption profile.

Cross Over Benches: Gowning Zone Barriers

Dedicated transition surfaces separate non-sterile and sterile zones, enforcing proper gowning procedures and preventing particle transfer into controlled environments. Strategic placement enables sequential donning protocols whilst maintaining clear segregation between classified areas.

1. Defined Transition Barrier

Creates physical and procedural boundary between clean and non-clean controlled areas, preventing cross-contamination during material and personnel movement.

2. Hygiene Compliance Platform

Smooth, cleanable surfaces support gowning protocols whilst integrated storage maintains sterile equipment within controlled zones.

3.Operational Efficiency

Reduces particle transfer into critical environments whilst streamlining gowning procedures for repeated cleanroom access cycles.

Bio Safety Cabinets: Triple Protection

Personnel Protection

HEPA-filtered exhaust air prevents exposure to biohazardous materials through negative pressure containment and directional airflow control.

Product Protection

HEPA filtration maintains ISO Class 5 conditions within work zone, protecting sensitive materials from environmental contamination during processing.

Environmental Protection

Closed exhaust systems with HEPA filtration prevent release of hazardous materials, ensuring regulatory compliance with environmental safety standards.

Ventilated enclosures engineered for safe handling of biohazardous materials in pharmaceutical, research, and diagnostic environments. Low-noise operation with regulatory compliance certifications.

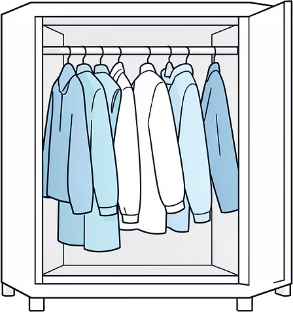

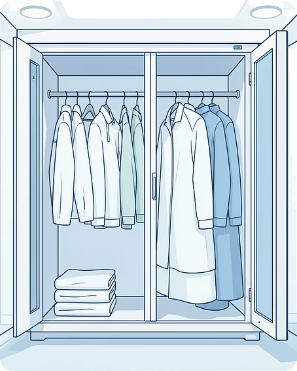

Garment Storage Cabinets

HEPA-Filtered Storage

HEPA-filtered exhaust air prevents exposure to biohazardous materials through negative pressure containment and directional airflow control.

Variable-Speed Blower

Adjustable airflow maintains particle-free storage environment. Durable construction with easy-to-clean surfaces supports regulatory audits.

Flexible Access

Movable cabinet configurations with curtain or door access options. Bottom vent discharge maintains laminar flow patterns.

Continuous Class 10 clean air supply with horizontal laminar airflow pattern maintains particle-free storage conditions.

Complete Cleanroom Integration

Material Transfer

Pass boxes and cross-over benches enable controlled material movement whilst maintaining class integrity across zones.

Personnel Control

Air showers and mist systems decontaminate before entry. Gowning areas enforce proper procedures for cleanroom access.

Storage Solutions

HEPA-filtered garment cabinets maintain sterile equipment. Dynamic dress cabinets preserve particle-free storage conditions.

Comprehensive equipment portfolio engineered to maintain contamination control in pharmaceutical, biotechnology, and advanced manufacturing. ISO-compliant systems support regulatory audits with full documentation and certification support.