Modular Solutions

Modular Solutions by Dozx Cleanrooms provide reliable clean environments using prefabricated wall systems, ceiling panels, modular cleanroom doors, view panels, integrated risers, and flooring solutions.

These modular systems are quick to install and easily adaptable to project requirements. They help maintain controlled airflow, pressure balance, and hygiene levels essential for effective contamination control. Dozx Cleanrooms’ modular solutions are used across pharmaceutical, healthcare, electronics, biotechnology, solar, cosmetics, and food sectors while allowing flexibility for future modifications or expansion.

Our Turnkey Modular Solutions

Modular Wall

Standard and customized solutions designed for durability, modularity, and global compliance.

Modular Ceiling

Seamless, contamination-resistant ceilings that ensure strength, insulation and easy integration.

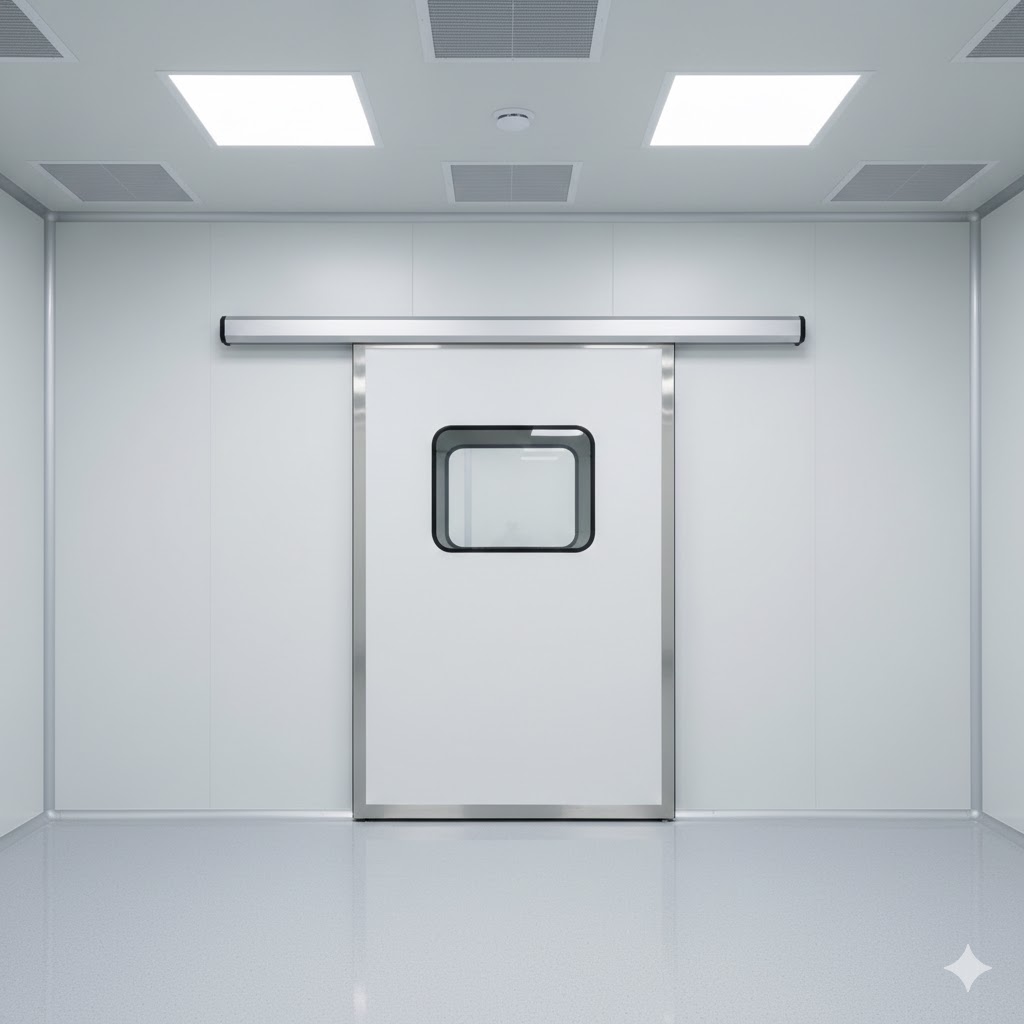

Modular Sterile Door

Air-tight and ergonomically designed, ensuring secure, contamination-free access with added safety and comfort.

Modular View Panels

Cleanroom-compliant, designed to provide clear visibility while maintaining safety, durability, and structural integrity under stringent controlled environment standards.

Integrated Risers

Return Air Risers preserve cleanroom integrity by efficiently directing return airflow to the HVAC system for advanced filtration and controlled recirculation.

Flooring Solutions

Crafted with durable, anti-static, and hygienic finishes, our surfaces are engineered to withstand rigorous operations while maintaining superior cleanroom integrity.

Cleanroom Wall Panels

Modular panels with extruded aluminum profiles and high-density insulated cores for fast installation, flexibility, and long-term durability.

Material Options

Premium surface materials for any cleanroom application.

- Pre-Coated / Powder Coated (0.6–0.8 mm)

- Stainless Steel (0.8–1.2 mm)

- HPL (3 mm)

Insulation

High-performance thermal and acoustic insulation cores.

- Rockwool

- PUF (FR Grade)

- PIR

Integrated Utilities

Supports full utility integration within the panel cavity.

- Electrical & data systems

- HVAC integration

- Piping & emergency systems

Key Benefits

Engineered for performance and efficiency.

- Space-efficient air returns

- Customizable finishes

- Panels up to 6 meters

- Faster installation

Modular Ceiling System

Self-supporting, walkable ceiling system designed to maintain cleanroom integrity while supporting airflow, lighting, and equipment. Available in 50, 80, and 100 mm thicknesses.

Key Features

Built for structural performance.

- Self-supporting steel structure

- Direct equipment installation

- Integrated HEPA/ULPA filters

- Lights & sprinkler integration

Benefits

Operational efficiency without compromise.

- No catwalks required

- Faster maintenance

- Reduced downtime

- Enhanced safety

Compliance

Meets global cleanroom standards.

- ISO 14644

- EU GMP

- USFDA

- Other cleanroom standards

Insulation

Thermal and acoustic core options.

- PIR

- Rockwool

- PUF (FR Grade)

Cleanroom Door Systems

Comprehensive range of door solutions engineered for contamination control, airlock management, and regulatory compliance.

Door Interlock

Controlled airlock access & contamination prevention

| Capacity | Up to 8 Doors |

| Logic | Single Door Open |

| Indicators | LED & Buzzer |

| Features | Air Pressure Control, Programmable |

Glazed Doors

Visibility with contamination control

| Thickness | 50 mm + Frame Ridge |

| Clear Width | 800 – 2000 mm |

| Clear Height | 2100 mm (Standard) |

| Glazing | 5 mm Glass (Single / Double) |

| Frame | Aluminum Extrusion |

| Hardware | SS 304 Handles |

Manual Sliding

Space-saving, cost-effective cleanroom access

| MOC | SS 304 / Powder Coated / HPL / Glass |

| Height | 2100 – 2800 mm |

| Width (Single) | 850 – 1750 mm |

| Width (Double) | 1600 – 3600 mm |

| Thickness | 45 mm |

| Sealing | Perimeter EPDM |

HPL Doors

Impact-resistant, aesthetic, hygienic spaces

| MOC | HPL 3 mm (Wear, flame, stain resistant) |

| Frame | 50 / 80 / 100 mm Aluminum Profile |

| Leaf | 45 mm thickness |

| Infill | PUF / Rockwool |

| Window | Double Tempered Glass |

Stainless Steel Doors

Corrosion-resistant hygienic environments

| MOC | SS 304 / 316 |

| Frame | 1.2 mm SS (Brush) / Powder Coated |

| Leaf | 45 mm |

| Infill | PUF / Rockwool |

| Leaves | Single / Double |

Automatic Sliding

Touch-free hygienic operation with interlocking

| MOC | SS 304 / Powder Coated / HPL / Glass |

| Height | 2100 – 2800 mm |

| Width | 900 – 3600 mm |

| Opening | Automatic |

| Operator | Hermetic |

| Sealing | Perimeter EPDM |

Hermetic Swing

Airtight barrier for cleanrooms, pharma, labs

| MOC | Powder Coated |

| Frame | 50 / 80 / 100 mm |

| Leaf | 45 mm, 0.8 mm GI |

| Infill | PUF / Rockwool |

| Leaves | Single / Double |

Fire Exit

Safe evacuation with contamination control

| Features | Flush wall alignment |

| Hardware | Panic hardware |

| Sealing | Airtight |

| MOC | GI / SS / HPL |

| Compliance | Fire & safety compliant |

Modular View Panel

Flush-mounted double-glazed window modules designed for seamless integration with cleanroom wall panels.

Construction

Premium laminated safety glass construction.

- 5 + 5 mm laminated safety glass

- Micro-perforated profile

- Integrated silica gel moisture absorption

- Fully silicone sealed

Anti-Fog Performance

Engineered to prevent condensation.

- Prevents fogging

- Supports cleanroom cleaning standards

- Enhanced durability

Design Options

Flexible edge profiles for integration.

- Rounded edge option

- Square edge option

- Double-layered glazing

Integrated Risers

Return Air Risers designed for leak-proof installation, controlled airflow, and cleanroom compliance.

Key Features

Engineered for airflow precision.

- Durable, corrosion-resistant

- Low maintenance

- Minimal particle contamination

- Stable air pressure

Compliance

Meets global regulatory standards.

- EU GMP

- FDA

- ISO 14644

Applications

Ideal for critical environments.

- Pharmaceutical manufacturing

- Biotech facilities

- Sterile manufacturing

Flooring Solutions

Premium hygienic flooring systems designed for pharmaceutical and controlled environments. Engineered for strict cleanliness, durability, and regulatory standards.

Epoxy Flooring

ndustrial-grade seamless flooring.

- Durable

- Chemical-resistant

- Seamless finish

PU Flooring

Flexible polyurethane flooring systems.

- Flexible

- Impact-resistant

- Easy maintenance

PVC Vinyl Flooring

Cost-effective hygienic flooring.

- Cost-effective

- Hygienic

- Resilient